09 APR. 2025

HORSE technologies engines to power 2026 Caterham Academy cars

– Horse Technologies to supply engines for the 2026 Caterham Academy, the UK’s leading amateur racing championship

– 2026 Caterham Academy cars to use high-performance 1.3-litre, 4-cylinder ‘HR13’ engine

– Horse Technologies is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres.

Horse Technologies, a division of Horse Powertrain and a leader in innovative and low-emission powertrain systems, has signed an agreement to supply engines for the 2026 Caterham Academy series.

The 1.3-litre, 4-cylinder ‘HR13’ turbo engine will power vehicles competing in its 2026 Academy Championship. Featuring direct injection technology, the high-performance gasoline engine with bespoke tuning will be able to deliver peak power of 130bhp (132PS) and a peak torque of 176Nm at 5,150rpm.

HR13 utilises a delta-shaped cylinder head to save mass and space, lower the centre of gravity, and improve thermal management of the engine. The exhaust manifolds are directly cast into the head for faster turbo response and exceptional low speed torque delivery.

The Caterham Academy is a unique championship exclusively for novice drivers. Established in 1995, its aim is to introduce anyone to the world of motorsport and enable them to realise their dream of becoming a racing driver. Today, the series is considered one of Britain’s most successful and over 1,400 drivers have competed in it.

Matias Giannini, Chief Executive Officer of Horse Powertrain, said: “It’s a privilege for us to supply our HR13 engine for the 2026 Caterham Academy Championship. Caterham is an iconic brand in the automotive and racing world, with a rich history and this is a unique opportunity to collaborate in their mission to discover the next generation of racing talent in the 2026 Academy series.”

Patrice Haettel, Chief Executive Officer of Horse Technologies, said: “We are very proud to see our technology achieve this new milestone. This collaboration with Caterham is a world-first application of the Horse Technologies HR13 engine to the world of racing, and reflects the performance, reliability, and expertise that drive everything we do.”

Bob Laishley, Chief Executive Officer of Caterham said: “The Caterham Academy has successfully introduced more than 1,400 rookie racing drivers to motorsport in the UK over the last 30 years. We’re very pleased to confirm our new partnership with Horse Technologies and look forward to working with their team on the introduction of this new turbo engine to our competitive rookie series from next season.”

The HR13 is produced at Horse Technologies’ Valladolid Motores plant in Spain.

DOWNLOAD DOCUMENT

19 MAR. 2025

HORSE enters maritime sector in partnership with Hybdor, for world’s first flex-fuel marine PHEV

– HORSE to supply its 1.3-litre, 4-cylinder ‘HR13’ engine to Hybdor, a Brazilian marine powertrain start-up

– Hybdor Duotech 200E system is a pioneering plug-in hybrid marine powertrain for use in Class 2 vessels (26 – 40ft)

– Deal marks HORSE’s first engine to be delivered to a marine customer

– HR13 to be one of the world’s first commercial marine engines capable of running on ethanol fuel

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

HORSE, a division of Horse Powertrain and a leader in innovative and low-emission powertrain systems, has today signed an agreement to provide engines for the marine powertrain system of the Hybdor Duotech 200E. This agreement is a world-first for HORSE, marking its first commitment to supply its engines beyond land vehicles.

Developed by Brazilian start-up Hybdor Tech, part of Espadarte Group, the Hybdor Duotech 200E uses a pioneering plug-in hybrid powertrain designed for use in yachts and Class 2 vessels (between 26 – 40 feet in length). HORSE will supply the combustion engine, its 1.3-litre, 4-cylinder Turbo Flex Fuel ‘HR13’ engine.

Like PHEV powertrains for land vehicles, the Hybdor Duotech 200E will be capable of operating in both pure-combustion and pure-electric modes. However, it will also feature a “boost” mode that combines both combustion and electric power to provide increased continuous power. The powertrain’s battery can also be charged while moving in combustion mode, along with being charged by plugging into a power outlet. When plugged in, the PHEV can be fully charged in just 90 minutes.

Produced locally at HORSE’s plant in Curitiba, HR13 can deliver peak power of 163PS (120W) and maximum of 250Nm of torque at 1,600rpm. The Hybdor Duotech 200E’s electric motors will supplement this with 25PS (18kW) peak power and 60Nm maximum torque.

The HR13 is optimised to run on the gasoline and ethanol flex fuels that are staples of the Brazilian market. This make the Hybdor Duotech 200E is one of the world’s first commercial marine powertrains that are designed to operate with commercially sold flex fuels, while also supporting pure-ethanol combustion.

Matias Giannini, Chief Executive Officer of Horse Powertrain, said: “Horse Powertrain plans to revolutionise every mobility category, which is why we’re incredibly excited to announce our first engine for use in a marine vessel. This new solution with Hybdor is a highly innovative application of our global technology leadership, leveraging our hybrid and alternative fuels expertise.”

Patrice Haettel, Chief Executive Officer of HORSE Division, said: “Our team is committed to developing more responsible and sustainable mobility solutions, for automotive and beyond. Our agreement with Hybdor is the first step into the marine market and aligns with our overarching energy transition goals. This new PHEV system, equipped with our HR13 engine produced in Curitiba, is a world-first in its provision of low-emission marine mobility through its use of ethanol.”

Thiago Sielski Marquardt, Chief Technology Officer of Hybdor Tech, said: “HORSE was the obvious partner for us as we created our unique Hybdor Duotech 200E. We needed a company that understood our vision and had the expertise and ability to deliver a low-emissions combustion engine, which could leverage the gasoline-ethanol flex fuels of the Brazilian market. This is a great example of two Paraná State businesses coming together to make a real difference.”

A plug-in hybrid marine powertrain system will improve the range of ships and boats while also reducing fuel consumption and emissions. It also enables a more comfortable experience during navigation by reducing vibration and noise.

DOWNLOAD DOCUMENT

29 JAN. 2025

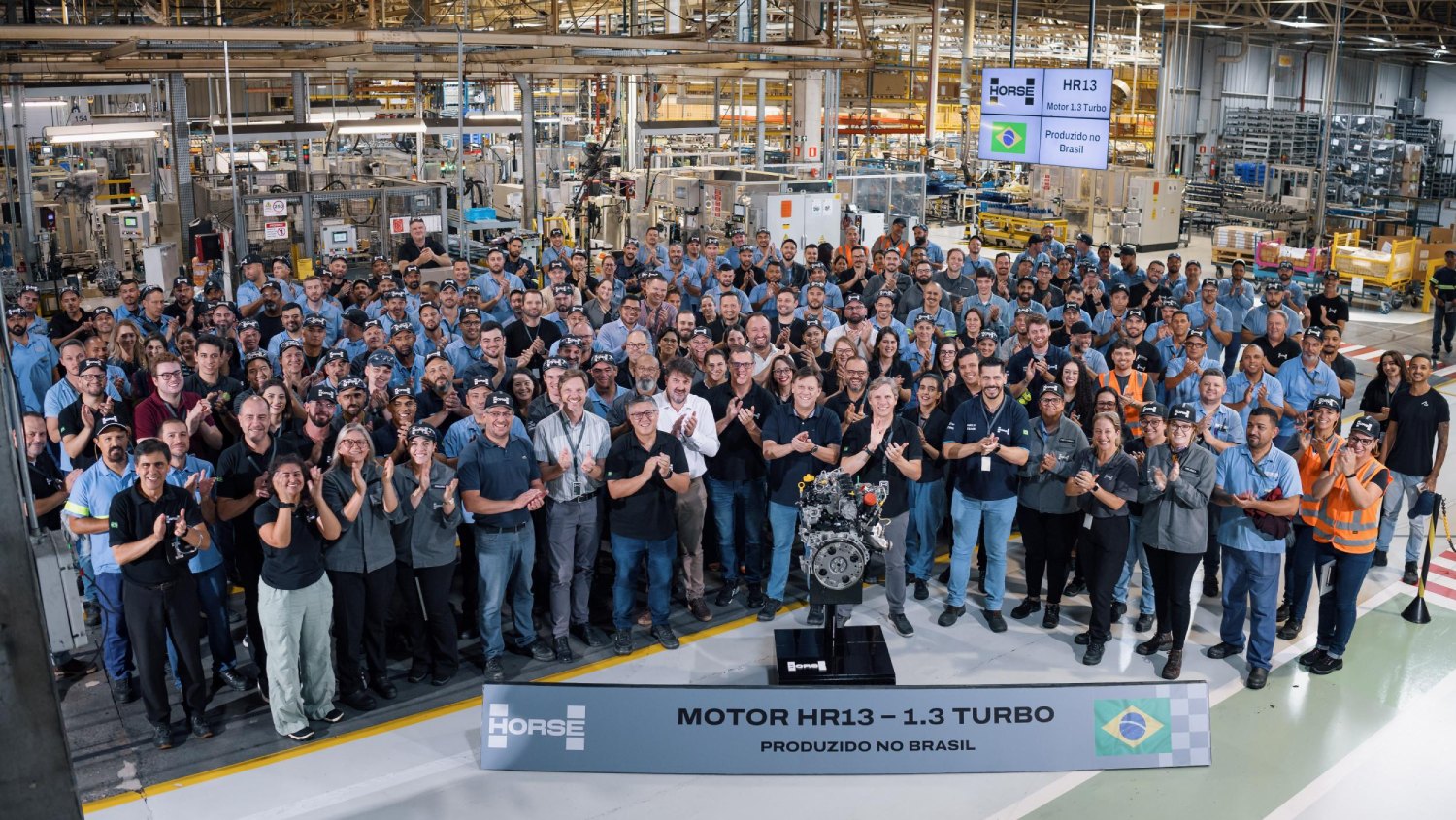

HORSE commences production of HR13 flex fuel engine at Curitiba

– HORSE commences production of its 1.3-litre, 4-cylinder ‘HR13’ turbo flex fuel engine at its facility in Curitiba, Brazil

– Engine delivers peak power of 163PS (120kW) and peak torque output of 250Nm from 1,600rpm

– New production facilitated by R$100 million investment in Curitiba plant

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

HORSE, a division of Horse Powertrain and a leader in innovative and low-emission powertrain systems, has started production of its 1.3-litre, 4-cylinder ‘HR13’ engine at its facility in Curitiba, Brazil.

The flex fuel variant of HORSE’s HR13 turbo engine has been engineered specifically for the South American market. It can seamlessly run on gasoline and ethanol blends that are staples of Brazilian mobility and is fully compliant with L8 emissions standards.

The powertrain delivers peak power of 163PS (120kW), as well as peak torque load of 250Nm at just 1,600rpm.

Commencement of HR13 production adds to HORSE’s growing production abilities in Brazil, following the start of production of its 1.0-litre, 3-cylinder ‘HR10’ engine earlier in 2024.

The HR13 benefits from a bespoke direct injection system that’s been developed specially for ethanol fuel use. Each cylinder is accompanied by a centrally mounted six-hole injectors operating at 200bar pressure, tailored for exceptional fuel atomisation that delivers effortless power and torque without impacting fuel efficiency.

Enabled by a recent R$100 million investment in the Curitiba facility, HR13 production will be a key output of the plant, which has capacity to produce up to 600,000 units annually across its portfolio of engines.

In 2024, HORSE also announced an investment in a gravity-casting process to produce aluminium cylinder heads for both the HR10 and HR13 engines, as well as expanding its powertrain and emissions testing facilities to service third-party manufacturers in the region.

Wesley Palma, Plant Director at HORSE Curitiba, said: “The start of HR13 production in Brazil demonstrates our commitment to delivering engineering and manufacturing solutions tailored to local markets. Specifically created with flex fuel capability, the highly efficient HR13 is perfectly suited to Brazilian OEMs and consumers. HORSE is particularly committed to localising key manufacturing processes, such as casting for the engine’s cylinder heads.”

Patrice Haettel, CEO of HORSE, said: “This move reinforces our commitment to the Brazilian market and South America. Our message has always been clear: there’s no such thing as a one-size-fits-all approach to global mobility, but instead tailor-made solutions that reflect regional needs. The HR13 reflects this ethos, powered by low-emissions flex fuels and optimised for Brazilian market needs.”

DOWNLOAD DOCUMENT

20 JAN. 2025

Andalusian Industry Minister visits HORSE Seville plant

– Regional Minister for Industry, Energy and Mining for the Government of Andalusia, Jorge Paradela visits Seville plant to see the initial phase of DB49 production

– HORSE Seville delivers economic stability to the area, employing more than 1,000 technicians and engineers from the local region

– The DB49 transmission is a clutchless, 15-speed unit which is designed for hybrid and plug-in hybrid vehicles

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

HORSE, a leader in innovative and low emissions powertrain systems, today welcomed Regional Minister for Industry, Energy and Mining for the Government of Andalusia, Jorge Paradela into its Seville plant to see first-hand production of its new DB49 transmission.

The HORSE Seville plant – which has been building transmissions for more than 60 years – delivers economic stability to the area, employing more than 1,000 technicians and engineers from the local region.

During his visit, Mr. Paradela walked along the production line of HORSE’s newest hybrid technology to see how it is built, as well as meeting several employees who are involved in in the manufacturing process.

The Minister also spent time with Javier Bernáldez, Plant Director to discuss the role hybrid vehicle technology will play in the region’s economy in the coming years. He also spoke with Rafael Vázquez, director of Industrial Excellence and Metaverse at HORSE, who highlighted the role of Seville in the company’s global strategy and the importance of technological neutrality in the search for sustainable mobility worldwide.

Jorge Paradela, Andalusian Minister for Industry, Energy and Mining, said: “HORSE is a clear example of a company committed to the energy transition, and stands out in its production of hybrid gearboxes such as the new DB49. The Andalusian government has supported this project with nearly €6 million via incentives from the regional government’s own funds to help make it a reality. This is alongside our other work with the automotive sector to tackle the challenge of delivering sustainable mobility solutions, including the €10 million invested in our CRECE stimulus plan.”

Javier Bernáldez, Plant Director at HORSE Seville, said: “The new DB49 transmission, built here in Seville, symbolises our commitment to the local [Andalusian] region and exporting around the world. We are honoured to host Mr. Paradela and showcase our world-class hybrid vehicle technology produced at the plant – including our all-new DB49 gearbox for HEV and PHEVs. HORSE believes that there’s no single path to sustainable mobility worldwide, and during his visit Mr. Paradela saw first-hand our commitment to versatile, technology neutral solutions that meet the needs of customers around the world.”

The new DB49 transmission produced at HORSE Seville is the first to be designed in-house by the company: a clutchless, 15-speed unit that produces a maximum torque of 470Nm and a peak output of 35kW. It features two electric motors for maximum versatility across a range of driving conditions and weighs just 99kg.

The plant, opened in 1966, has built more than 32 million units over its lifetime. In 2024, it produced 666,670 transmissions. More than 60% of the plant’s output is exported beyond Spain.

DOWNLOAD DOCUMENT

15 JAN. 2025

HORSE begins production of powerful and efficient emotor

– HORSE begins production of new compact eMotor at Aveiro facility in Portugal, designed for use in full hybrid and plug-in hybrid applications

– New eMotor delivers max power of 49kW and max torque of 212Nm, capable of powering vehicles at up to 130km/h in EV mode

– Four new production lines added at Aveiro allow construction of up to 160,000 units a year, including a three-head winding tool for faster and more accurate production

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

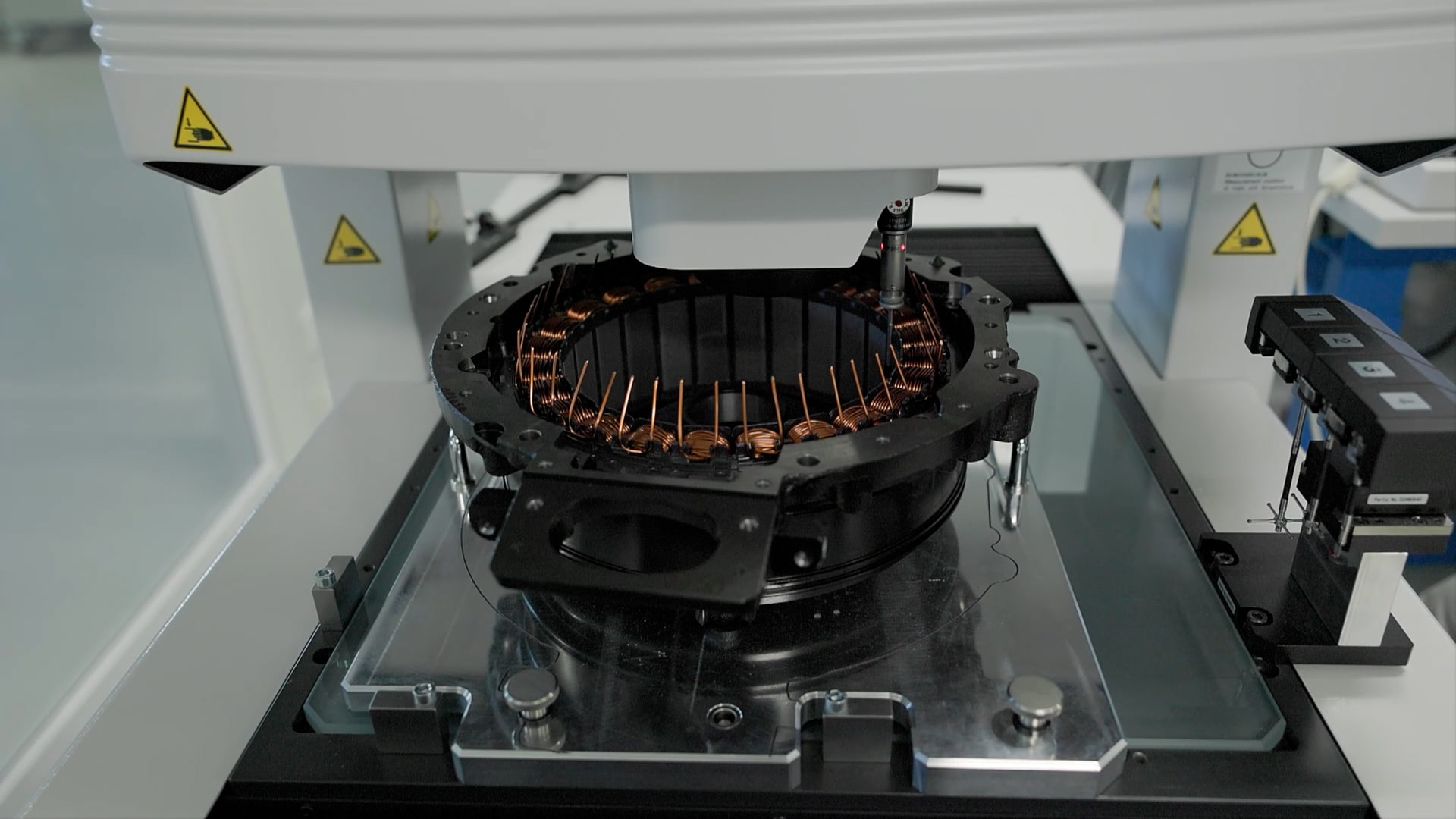

HORSE, a leader in innovative and low emissions powertrain systems, has started production of its eMotor at its Aveiro facility in Portugal. The new radial flux eMotor uses the latest technology and materials to deliver exceptional performance and efficiency for next-generation plug-in and hybrid vehicles.

The eMotor is initially designed for use in hybrid powertrain architectures using HORSE’s HR12, HR16 and HR18 internal combustion engines. Capable of being used in both full hybrid and plug-in hybrid applications, the eMotor delivers maximum power of 49kW and 212Nm of torque.

Patrice Haettel, Chief Executive Officer at HORSE, said: “The start of eMotor production at Aveiro reinforces HORSE’s commitment to delivering efficient powertrains using the latest technology. With its compact design, and the ability to work in 100% electric mode, this powerful and efficient motor is perfect for many types of hybrid vehicle. Once again, HORSE has demonstrated its credentials as the ideal partner for our customers on their ongoing electrification journeys.’

Featuring a compact design, the eMotor is mounted between the internal combustion engine and the transmission, delivering two driving modes: 100% electric and hybrid.

In electric mode, the eMotor drives the wheels directly at speeds of up to 130km/h. In hybrid mode, the eMotor assists the internal combustion engine to deliver enhanced acceleration and improved fuel efficiency. When the vehicle is decelerating, the eMotor acts as a generator, recovering kinetic energy that is stored in the vehicle’s battery.

To enable this production, HORSE’s Aveiro plant has invested in four new lines that allow the facility to manufacture up to 160,000 units a year. Each line has a dedicated function for various stages of production: including machining of the motor housing, rotor shaft, and magnet, along with final assembly. Among these state-of-the-art lines is a three-head precision winding machine, allowing faster and more accurate construction of the eMotor’s core.

Download document

09 JAN. 2025

Horse Powertrain names six new executive leaders to drive innovation and operational excellence

Horse Powertrain Ltd today announced six strategic appointments to its Executive Management Team (EMT), expanding its leadership structure to drive forward the company’s transformation strategy.

The new executives will report directly to CEO Matias Giannini, joining current EMT members CFO Lee Ma, CHRO Juan Ferrera, and Divisional CEOs Ruiping Wang and Patrice Haettel.

The appointments are:

- Clemence Auroy-Vernin, Chief Legal and Compliance Officer.

- Helene Carlson, Chief Communications and Public Affairs Officer.

- Ingo Scholten, Chief Technology Officer.

- Arnaud Fages, Chief Strategy & Partnerships Officer.

- Luca Stoppelli, Chief Purchasing Officer.

- Michael Fleiss, Chief Sales Officer.

Clemence, Helene, Ingo, and Michael will also maintain their current responsibilities within their respective divisions at Horse Powertrain

“I am delighted to welcome these six leaders to Horse Powertrain’s leadership team. Their diverse perspectives and experience will play a vital role as we accelerate our transformation toward becoming one unified global company. Together, we will drive innovation and operational excellence, ensuring we deliver value and reliability to our customers and stakeholders as we help push the industry’s transition to net zero.” said Matias Giannini, CEO of Horse Powertrain.

Download document

21 NOV. 2024

HORSE certified as a great place to work

– HORSE achieves independent certification as a Great Place to Work

– Employees worldwide responded positively to survey, with HORSE rated highly for Pride, Fairness, and Community

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres.

HORSE, a division of Horse Powertrain and a leader in innovative and low-emission powertrain systems, has achieved Great Place to Work certification, one of the world’s well-recognised awards for high-quality workplaces. This follows a global survey of HORSE’s workforce by the independent Great Place to Work organisation.

This recognition comes only one year after HORSE began operations and reflects its strong commitment to creating a positive and inclusive work environment. Overall, positive survey responses reached the requirements for Great Place to Work certification.

The survey was conducted in September 2024 and spanned seven countries, encompassing the organisation’s eight factories, three R&D centres, and global headquarters. HORSE achieved the highest ratings in three key areas:

- Pride: “I’m proud to tell others I work here”

- Justice: “The company promotes inclusive behaviour, avoids discrimination, and is committed to fair appeals.”

- Community: “I consider myself a member of a close-knit team.”

These results highlight the commitment of global teams to HORSE’s mission of providing next-generation mobility solutions for a more responsible, sustainable, and inclusive future. They also signal HORSE’s success in building a strong organizational culture in its first year of operations.

Patrice Haettel, Chief Executive Officer of HORSE, said: “Since embarking on this journey a year ago, there’s never been a shred of doubt about the quality of our people and operations. I’ve had the opportunity to visit our factories and workplaces and see first-hand the unique spirit of our teams, along with their enthusiasm and commitment. This spirit has only consolidated over the past year, and it’s our collective responsibility to continue to strengthen it. The true success of HORSE lies in the people who make up this great family, and I am deeply proud of what we are building together.”

Juan Ferrera, Chief People & Organisation Officer, said: “This result reflects that HORSE’s efforts to promote an inclusive and equitable culture are paying off. Our people are the key to HORSE’s success, which is why we are committed to continually strengthening our work environment – our hope is to make this company a truly great place to work for everyone.”

All HORSE workplaces worldwide, located in Argentina, Brazil, Chile, Spain, Romania, and Turkey, achieved the local Great Place to Work certification, except Aveiro plant in Portugal, which is close to the minimum requirements.

To build on these impressive results, HORSE is designing a global action plan to drive further improvement in employee satisfaction, working closely with local and global HR teams to to further develop team engagement and wellbeing across all its sites.

DOWNLOAD DOCUMENT

11 NOV. 2024

HORSE net-zero emissions target receives Science Based Targets initiative (SBTi) approval

– HORSE has received Science Based Targets initiative (SBTi) approval for its greenhouse gas (GHG) reduction targets

– Targets include net-zero emissions across HORSE’s entire value chain by 2050

– Key 2030 targets*:

Reduce Scope 1 and 2 GHG emissions by 42%

Increase renewable electricity sourcing from 71% to 100%.

Reduce Scope 3 GHG emissions from the use of sold products by 25%

* using 2023 as the base year

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

HORSE, a division of Horse Powertrain and a leader in innovative and low emissions powertrain systems, has had its ambitious emissions target – to be net-zero emissions across the entire value chain by 2050 – approved by the Science Based Targets initiative (SBTi).

As part of its near-term objectives, HORSE has committed to reducing absolute Scope 1 and Scope 2 emissions by 42% by 2030.

In addressing Scope 3 emissions, HORSE has pledged to reduce GHG emissions from the use of its sold products by 25% by 2030.

These reductions will be achieved through various initiatives, including increasing low-carbon engine sales to 60% of total sales, purchasing 100% renewable electricity, using biomethane in production plants, and implementing energy efficiency measures, among other strategies.

These targets are aligned with HORSE’s broader sustainability strategy (ESG Plan 2030) of not only providing innovative solutions for markets transitioning towards more sustainable futures, but also being a transformation agent within the automotive industry towards decarbonisation.

Patrice Haettel, CEO of HORSE, said: “Achieving this approval from Science Based Targets initiative (SBTi) demonstrates just how seriously we are taking the sustainability of our business and our planet. We are committed to giving more back than we take and it’s why we will continue with our mission to develop and deliver innovative power solutions that support a decarbonised future. These targets are clear demonstration of our drive to create meaningful change within the automotive industry.”

Science Based Targets initiative (SBTi) is a global organisation developing standards and tools to create science-based targets to help companies identify and reduce greenhouse gas (GHG) emissions and future-proof business growth.

Targets are considered ‘science-based’ if they are in line with what the latest climate science deems necessary to meet the goals of the Paris Agreement.

DOWNLOAD DOCUMENT

17 OCT. 2024

HORSE to install 11,700 new solar panels at Aveiro factory in Portugal

– HORSE begins 14-month project to install two new solar farms at Aveiro facility in Portugal

– Aveiro’s solar park will produce 16GWh of electricity a year for the plant, 30% of annual requirement, reducing annual CO2 emissions by 3,167 tonnes

– Once completed Aveiro’s solar installation will be one of the largest private solar parks in Portugal, and meet up to 30 per cent of factory’s electricity needs

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

HORSE, a division of Horse Powertrain and a leader in innovative and low emissions powertrain systems, has begun the planned installation of two new arrays of solar panels that will supply renewable electricity to its plant in Aveiro, Portugal. Once complete, solar energy will meet up to 30% of the factory’s annual electricity needs and reduce its annual CO2 emissions by 3,167 tonnes.

Installed as part of HORSE’s decarbonisation strategy, the new photovoltaic arrays have been funded with the support of a grant from the Portuguese Recovery and Resilience Plan. In total, the new photovoltaic arrays represent an investment of €3.5 million.

Raynald Joly, General Manager at HORSE Aveiro, says: “This new photovoltaic park will enable HORSE Aveiro to meet up to 30% of its energy needs with green electricity. This is all part of HORSE’s broader commitment to decarbonising mobility, delivering a more sustainable future, and powering tomorrow.”

Part of the solar installation will be mounted on the roof of the facility and will consist of 2,800 solar panels that will generate 1.6MWp. The other part of the array will be ground-based and consist of 8,900 panels calculated to generate 5.0MWp. Annually, HORSE Aveiro expects both produce 16GWh of clean and sustainable electricity a year.

Construction and installation will last fourteen months and will be undertaken by ENGIE Hemera, one of Portugal’s leading solar engineering specialists.

Powering a world-leading automotive plant

HORSE Aveiro already boasts one of the largest private fields of photovoltaic panels in Portugal, with this new project further expanding its lead.

The plant has over forty years of operational excellence in manufacturing gearboxes and engines, and has recently ventured into manufacturing critical electronics components for hybrid-electric vehicles (HEVs) and plug-in hybrid-electric vehicles (PHEVs).

Employing 1,300 workers, HORSE Aveiro boasts state-of-the-art Industry 4.0 technologies, including production lines that make use of robotic mobile workstations in place of traditional conveyer belts.

DOWNLOAD DOCUMENT

14 OCT. 2024

HORSE hybrid engine to power all-new Dacia bigster’s flagship model

– HORSE 1.8-litre, 4-cylinder combustion engine to feature in the All-New Dacia Bigster HYBRID 155 – the flagship model of the range

– New engine for the HYBRID 155 powertrain the first entirely designed and produced by HORSE since its creation in July 2023

– Produced at HORSE’s plant in Valladolid, engine to provide up to 107bhp of power

– Powertrain to also feature two electric motors, a 1.4kWh 230V battery, and a clutchless gearbox

– HORSE is a division of Horse Powertrain, a global leader in hybrid and combustion powertrain solutions across 17 plants and 5 R&D centres

HORSE, a division of Horse Powertrain and a leader in innovative and low emissions powertrain systems, today announces that its engine will be powering the All-New Bigster HYBRID 155 – the flagship model of Dacia’s newly-revealed SUV range.

The Dacia model will be the first vehicle to use the HYBRID 155 powertrain. At the heart of the All-New Bigster HYBRID 155 will sit one of HORSE’s internal combustion engines, produced at its plant in Valladolid, Spain. The 1.8-litre, 4-cylinder model will provide up to 107bhp of power, and is the first engine to be designed and produced entirely in-house by HORSE since its creation in July 2023.

Matias Giannini, Chief Executive Officer of Horse Powertrain, said: “The flagship All-New Bigster will be a perfect showcase of Horse Powertrain’s hybrid powertrain leadership and expertise. As the first engine produced entirely within our HORSE division, this moment is extremely significant for the automotive industry: Horse Powertrain has now proved that it can handle the full life cycle of engine development and production. With our consoliated powertrain expertise, we are helping brands and OEMs to innovate and bring new offerings to market at an unparalleled pace.”

Patrice Haettel, Chief Executive Office of HORSE, said: “Our latest high-efficiency, market-leading engine will ensure that the All-New Bigster offers incredible performance and efficiency in all conditions and driving modes, providing a convenient and low-emission vehicle that raises the bar for the SUV class. This is an incredible moment for our engineers and Valladolid team members, who have made company history by bringing to market the very first engine developed and produced entirely by HORSE.”

Next-generation electrified powertrain

Alongside HORSE’s engine, the HYBRID 155 powertrain in Dacia’s All-New Bigster features a 50bhp electric motor, a high-voltage starter/generator electric motor, and a 1.4kWh 230V battery. The HYBRID 155’s clutchless gearbox has four gears for the HORSE combustion engine, and two for the electric motors.

The All-New Bigster HYBRID 155’s powertrain will have market-leading performance and power, including a full tonne of towing capacity. In terms of efficiency the model significantly improves on the existing HYBRID 140 powertrain, offering a 6% reduction in fuel consumption and emissions. Its regenerative braking, high battery energy recovery capacity, and efficient gearbox means that the HYBRID 155 can remain in all-electric mode up to 80% of the time in the city – and can always start in all-electric mode.